CHEMICAL BLOWING AGENT

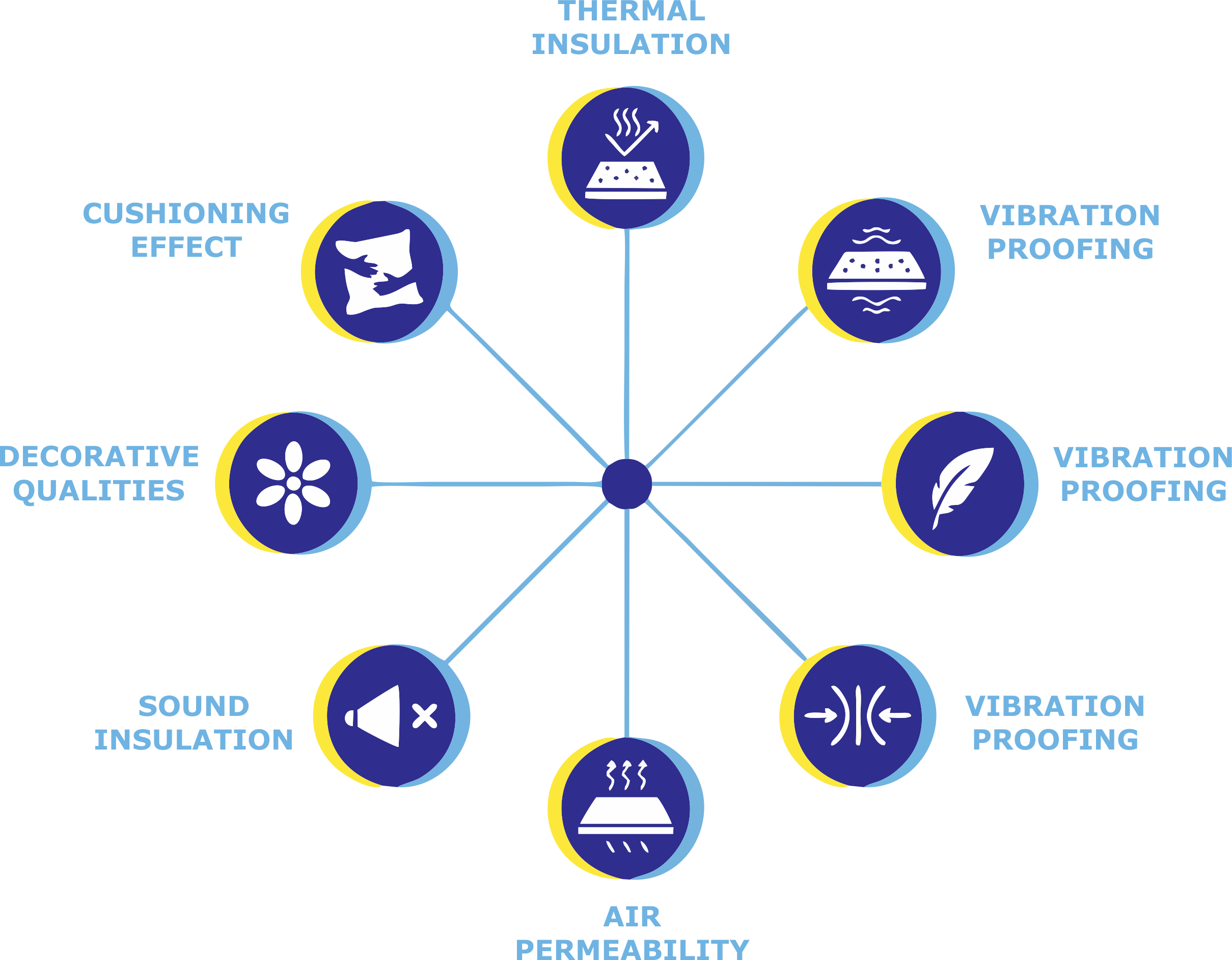

Chemical Blowing Agent dapat membentuk gelembung di dalam matriks, seperti plastik dan karet. Matriks ini dapat diberikan fungsi sekunder seperti insulasi termal, efek bantalan, kemampuan mengapung, kedap getaran, kedap getaran, insulasi suara, serap suara, aksi penyegelan, permeabilitas udara, kualitas dekoratif, dan bobot ringan.